LIQUID FILLING LINE

We offer Online Visual Bottle Inspection Machine that is fabricated using S.S square pipes and is supported on adjustable bolts. These are widely used in pharmaceutical processing industries all across the globe and consist of three-track conveyor with stainless steel structure and square pipes with moving S.S. slat chain and supported on adjustable bolts. These are incorporated with hood and lighting arrangement with visual inspection background of alternate black and white color

We offer Online Visual Bottle Inspection Machine that is fabricated using S.S square pipes and is supported on adjustable bolts. These are widely used in pharmaceutical processing industries all across the globe and consist of three-track conveyor with stainless steel structure and square pipes with moving S.S. slat chain and supported on adjustable bolts. These are incorporated with hood and lighting arrangement with visual inspection background of alternate black and white color

Operation :

- The central conveyor belt brings the bottle from the capping machine conveyor

- These bottles are automatically bifurcated on the two adjoining conveyor belts and further on the side tables for operator sitting on either side of the table

- The operator sin turn pick up the bottles and visually inspect the bottles in the alternate white and black background to check for any particles in the liquid filled, sealed and breakage of bottle

- After inspection the bottles are placed in the central track

Technical specifications

- Lighting arrangement for visual inspection

- Independent drive mechanism

- Variable speed drive and starter

- Capacity 40 to 120 bottles minute

- Demotion of belt 6’ x 3’x 5’

- Motor 1.5 HP gear box 22/50

- No. of operators required 4 (max)

- Power supply 2HP

Our world class range of Turn Table 30 Dia (GMP Model) is fabricated from premium quality raw material and is efficient in offering high functionality. With credible services over the year we have successful achieved the reliance of our esteemed clients worldwide.

Our world class range of Turn Table 30 Dia (GMP Model) is fabricated from premium quality raw material and is efficient in offering high functionality. With credible services over the year we have successful achieved the reliance of our esteemed clients worldwide.

- Diameter: 30”x 30”

- T.T. Cabinet body.

- Round plat dimension 30”

- Motor 0.5 HP & gear 17/50,

- Speed 3 steep pulleys (A)

- One stares on/ off

- Dimension 3’ x 3’

- Power supply 0.5HP

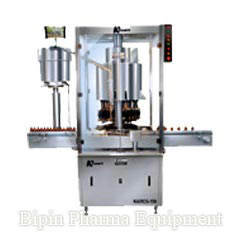

Our precision engineered 12 Automatic ROPP Cap Sealing Machine is meticulously designed and is ideal for effective and reliable sealing of bottles and containers with aluminum caps of different sizes All the contact parts are fabricated using stainless steel and conforming to the latest GMP norms.

Our precision engineered 12 Automatic ROPP Cap Sealing Machine is meticulously designed and is ideal for effective and reliable sealing of bottles and containers with aluminum caps of different sizes All the contact parts are fabricated using stainless steel and conforming to the latest GMP norms.

Key Features

Following are the unique features of our manufactured range:- Output: 60 bottles per mint

- Designed to suit a variety of containers and caps

- Non Flame proof model is also available

- Height of conveyor belt of this machine is adjustable from 800 mm

- Maximum bottle demotion 75mm, maximum height 200mm

- No cap no selling

- Erection and commissioning is done easily without any foundation.

- Cap diameter: 22,25,28 with machine

- Position of bottle rest as well as sealing head can be lowered

- Sealing heads are easily interchangeable

- Conveyor 6’, 3 ¼”x 3mm thicknesses S.S. 304

- Dimension (L.W.H) 6’X4’, Height -5 ft

- Power supply 2HP

Our Automatic Rotary Bottle Washing Machine reflect our intricate design of out trained professionals which breathe in quality, durability and flawlessness making these machines highly demanded in markets across the globe.

Features

Essential Features of the machine:

- Designed to clean vials, bottle and similar containers with utmost precision. Distinct processing operation are carried out by the machine. Machine works on A/C current.

- Designed to clean vials, bottle and similar containers with utmost precision. Distinct processing operation are carried out by the machine. Machine works on A/C current.

- Independent line connections for various systems is provided, along with an additional connection for washing & rinsing the outside of the container.

- The driving machine is placed at the bottom part and it is equipped with a cone pulley and friction wheel for controlled movement.

- The rotation speed is one round per minute with the capacity to wash 2000 to 9000 bottles an hour.

- The rotting plate is fitted with 16 manifolds which have 5 spraying tulips/ bottle holders each.

- The holders are fitted with spray nozzles with adjustable neck rings for washing various sized of bottles.

- 5 stations are provided which include one for spraying on top of bottles which is for the external cleaning. The remaining 4 stations can be connected to jets of detergent, steam/ hot water as per client requirement.

Technical Specification

| Mohel | BPE- 64 | BPE – 96 | |

|---|---|---|---|

| Output / Hour | 2600 to 6000 Nos. | 4300 to 9000 Nos. | |

| No. of Container Holder | 64 | 94 | |

| Direction of Movement | Clock wise | ||

| Electrical Specification | Main Motor | 0.5 HP / 415 Volts / 50 Hz. | |

| Pump Two Nos. | 1HP X 2 = 2 HP / 415 Volts / 50 HZ | ||

| Electric Heater | 3 Kw. | ||

| Tank Capacity | 75 Ltrs. S.S. 304 (2 Nos.) | ||

| Wash Cycle | 4 inner + 1 Outer | ||

| Working heights | 860 to 910 mm | ||

| Machine Dimensions (In mm) | 1500 (L) x 1750 (W) x 1300 (H) | 1500 (L) X 1750 (W) x 1300 (H) | |

| Case Dimensions (In mm) Two Cases | Machine | 1600 (L) x 1600 (W) x 1550 (H) | 1600 (L) x 1600 (W) x 1550 (H) |

| Tanks | 1550 (L) x 1000 (W) x 1550 (H) | 1550 (L) x 1000 (W) x 1550 (H) | |

| Net Weight | 450 Kgs. | 550 Kgs. | |

| Gross Weight | 750 Kgs. | 900 Kgs. | |

| Change parts required | (A) Neck Dia: Bottle holding pocket. (B) Flat Container: Special type of cup. | ||

Input Specification

| Container Size | Round Shape | Ø30 mm to Ø100 mm Respectively Height 50 mm to 270 mm Ø20 to Ø28 Neck | Ø30 mm to Ø80 mm Respectively height 50 mm x 270 mm Ø20 to Ø28 Neck |

| Flat / Square | 30 mm to 100 mm (Length) Respectively10 mm to 50 mm (Width) Respectively height 58 mm X 190 mm | 30 mm to 80 mm (Length) Respectively 10 mm to 50 mm (Width) Respectively height 58 mm x 190 mm |

Consumption of Water

| Model | BPE – 64 | BPE – 94 |

|---|---|---|

| First Wash | 200 Ltr/ Hr. | 230 Ltr./Hr. |

| Second Wash | No consumption as such, water loss during re-circulation shall be compensated OR Air Wash. | |

| Third Wash | 200 Ltr/Hr. | 230 Ltr./Hr. |

| Fourth Wash | No consumption as such, water loss during re-circulation shall be compensated OR Air Wash. | |

| Outside Wash | 200 Ltr/Hr. | |

Salient Features

- Geneva Mechanism.

- Four inner (Included one air wash) & one outer.

- Sequence of washes to customer’s choice.

- Easy operation.

- Stationary nozzles eliminate contamination of water cycles.

- Easy loading and unloading.

- Individual solenoid valve for each washing sequence, that eliminates carbon plate and other accessories reduces leakage and maintenance to minimum

- Higher capacity centrifugal pumps to wash bigger bottles (500 & 1000 ml.).

- The stationary nozzles avoid chipping of bottle necks.

- Pumps and tanks are mounted on portable stand for easy maintenance.

- Bottle guide system especially for lightweight bottle.

- Pumps and Tanks are mounted on portable stand for easy maintenance.

- Separate panel control to avoid any short circuit due to spraying of water.

- S.S. glycerin fill pressure meter.

Utility Requirement

| Electrical supply | 3 Phase + Neutral + Earthing |

| Electrical load | 2 KW + 3 KW for heater |

| Air Pressure | Minimum: 6 Bar pressure 5 CFM |

The salient features of the Automatic Liquid Bottle Filling machine are as follows:

The salient features of the Automatic Liquid Bottle Filling machine are as follows:

Process of Operation

- Containers moving on the SS Slat Conveyor belt are fed by filling nozzles through a settable twin pneumatically operated stopper system.

- The twin pneumatically operated stopper system and reciprocating nozzles precisely match the centre of the nozzles below to avoid the spillage of liquid on the conveyor belt.

- To minimize the foaming, adjustable nozzles reciprocate according to the dosage of filling. The nozzles go up slowly from the bottom level of the bottle towards the neck during its filling takes place.

- The dosing block with a hexagonal bolt fitted below the syringes allows easy setting of the fill size.

Automatic Liquid Bottle filling Machine Manufacturer in India

Specification| Model | BPE – 100 | BPE – 150 | BPE – 200 |

|---|---|---|---|

| Output/Hour | 2000 to 2500 | 2500 to 3600 | 4200 to 4500 |

| Direction of Movement | Left to Right | ||

| Number of head/syringe | 4 Nos. | 6 Nos. | 8 Nos. |

| Container Size | Round Shape | (A) Ø28 mm to Ø100 mm (B) Height 58 mm to 240 mm (Height option for other bottle height available) | (A) 15 mm to 100 mm (Length) (B) 10 mm to 50 mm (Width) (C) 58 mm x 240 mm (Height option for other bottle height available) |

| Flat / Square | 1.5 HP / 415 Volts / 50 Hz. | ||

| Height of Conveyor | 860 mm to 910 mm adjustable. | ||

| Machine Dimensions | 2135 mm (L) x 1150 mm (W) x 1610 mm (H) | 2135 mm (L) x 1350 mm (W) x 1610 mm (H) | |

| Case Dimensions | 2350 mm (L) x 1350 mm (W) x 1650 mm (H) | 2350 mm (L) x 1550 mm (W) x 1650 mm (H) | |

| Net Weight | 600 kgs. | 700 kgs. | 850 kgs. |

| Gross Dimensions | 850 kgs. | 950 kgs. | 1100 kgs. |

| Change parts required | Change parts required | ||

| Container Neck Diameter | Minimum 22 mm | |

| Container Size | Round Shape | (A) Ø28 mm to Ø100 mm (B) Height 58 mm to 240 mm (Height option for other bottle height available) |

| Flat / Square | (A) 15 mm to 100 mm (Length) (B) 10 mm to 50 mm (Width) (C) 58 mm x 240 mm (Height option for other bottle height available) | |

Online visual bottle inspection Machine manufacturer in India